The raw materials used in our production equipment are purchased through regular channels. The material itself has high precision and good stability, and the production equipment has accurate and stable performance. Every batch of raw materials arrives, the quality inspection department will inspect the materials in accordance with the "Incoming Inspection Procedures" to ensure that the raw materials are qualified. Unqualified and non-compliant are returned and exchanged to ensure the rigor of raw material import .

The company has a complete department for inspection. The raw material acceptance system and procedures are as follows:

1. Sampling method

For the acceptance of raw materials and outsourcing parts, sampling inspection is not carried out, but full acceptance is carried out; for outsourcing parts and parts, random sampling inspection is carried out

2. Number of samples

For the acceptance of raw materials and outsourcing parts, no sampling inspection will be carried out, and full acceptance will be carried out; the sampling quantity of purchased parts and parts shall be 30% of the incoming quantity. In addition, if the incoming quantity is within 10 (including 10) Carry out the full acceptance inspection. When the warehousing quantity exceeds 10, but the sampling amount calculated by 30% does not reach 10, the sampling inspection shall be carried out according to the sampling amount of 10.

3. Check items

(1) Component warehousing acceptance inspection items include: appearance, packaging, product integrity, qualification certificate, input resistance and output resistance, a total of six items. The warehousing inspection form should indicate the time of entry, supply unit, and variety , Specifications, place of production, storage quantity, random inspection quantity and serial number, storage place, acceptance person, acceptance time.

(2) The test line warehousing acceptance inspection items include: appearance, packaging, product integrity, certificate of conformity, and whether the power is normal. The warehousing inspection form should indicate the time of entry, supply unit, variety, and specification , Origin, warehousing quantity, random inspection quantity and serial number, storage place, acceptance person, acceptance time.

(3) The inspection items for the acceptance inspection of aluminum alloy boxes include: appearance, packaging, product integrity, and certificate of conformity. The acceptance time, supplier, variety, specification, origin, Storage quantity, random inspection quantity and serial number, storage place, acceptance person, acceptance time.

(4) The inspection items for the acceptance inspection of mechanical parts include: material specifications (including thickness, length, width), type, origin, quantity, and whether there is a material report. There are five items in the warehouse acceptance form. , Supply unit, transport unit, variety, specification, place of production, warehousing quantity, random inspection quantity, storage place, inspector, and acceptance time.

4. Inspection methods and inspection conditions

The inspection conditions (i.e. prerequisite) for the acceptance of raw materials, outsourcing parts, purchased parts, and spare parts are that the items listed on the supply list issued by the supplier are consistent with the items listed in our company's order list; specific inspections The method is: according to the item name, specification and model listed in the order list, check whether the item is consistent, then check whether the specification and model listed in the factory certificate of the item are consistent with the actual product, and finally follow the technical data listed in the item's factory certificate or manual Related inspections.

5. Inspection equipment/instruments

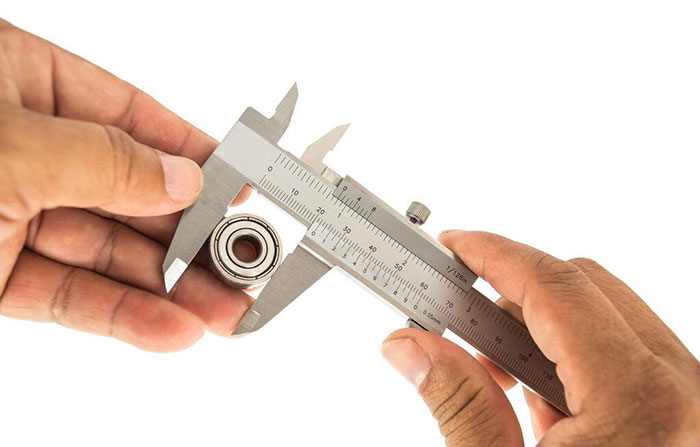

The inspection equipment/instruments for the warehousing and acceptance of raw materials, outsourced parts, purchased parts, and parts are mainly tape measure, simulator, and multimeter.

6. The style of the inspection report

The format of the inspection report is detailed in the "Incoming Inspection and Acceptance Form". The format and inspection items of the incoming inspection and acceptance form can be slightly modified according to actual needs.

7. The principle of eligibility judgment

The supply list is consistent with the items listed in the order list; the product packaging is consistent with the actual product; the name, model, specification and related technical data marked on the certificate are consistent with the actual product, it is qualified, and any inconsistency is considered unqualified.

8. How to deal with unqualified

The items in the supply list and the order list are inconsistent, that is, the goods sent by the supplier are inconsistent with the goods ordered by our company, and the supplier should be contacted in time for return/exchange;

The product packaging is inconsistent with the actual product. If the actual product is the same as the product ordered by our company, you can contact the supplier to replace the packaging. If the physical product is inconsistent with the product ordered by our company, you should contact the supplier in time for return/replacement;

The name, specification, and model marked on the certificate are inconsistent with the actual product, but the actual product is consistent with the product ordered by our company, and the supplier should contact the supplier to replace the certificate; if the name, specification, and model marked on the certificate are consistent with the actual product, but relevant If the technical data is unqualified, contact the supplier for return/exchange.

9. Warehousing acceptance form

The warehousing acceptance form must be filled in truthfully during the warehousing inspection and acceptance of raw materials, outsourced parts, purchased parts, and parts, and the warehousing acceptance form for the current year shall be bound into a book by category at the end of the year. The format of the warehousing acceptance form can be designed according to actual needs, but it must include all the inspection items listed in Article 3 of this regulation.

To produce high-quality products, modern enterprises need not only high-quality technical personnel, but also precise equipment, so that the various quality indicators of the products can meet the requirements of relevant standards. To ensure the high-precision performance of equipment for a long time, the company has set up a full-time quality inspection department to arrange long-term and experienced equipment mechanical maintenance and electrification maintenance engineers to regularly inspect different equipment at different inspection intervals. Provide a strong guarantee for the production of high-quality products.