Dry test transformer plays an obvious role in high voltage test tests, which is one of the more frequent instruments used by the majority of testers. Let's briefly understand the standard test steps of dry test transformer to help you improve the test efficiency.

One, dry test transformer single use

1. Before the test, the high-voltage tail "loot" end of the test transformer should be reliably grounded, otherwise the personal and equipment safety will be endangered.

2, before operation must be familiar with the test transformer and power control box electrical principle and use method.

3. Wire according to the wiring diagram.

4, preparation and safety measures in place, air test equipment.

5. Connect the subject.

6, close the power supply, control box (Taiwan) power indicator light.

7, press the closing button, the closing indicator light.

8, clockwise uniform pressure, watch the voltmeter to reach the stage voltage amplitude and the condition of the test until the rated test voltage.

9, continue to stipulate the pressure time and watch the ammeter and the test.

10. When the voltage withstand time is up, watch the kV meter and quickly return the voltage regulator to zero.

11, with the discharge rod through the resistance discharge, and then directly grounded discharge.

12, the high voltage part may be charged part one by one discharge, change or remove the high voltage wire lead, so that a (phase) test is terminated.

Two, dry test transformer series excitation

1, an overview of the

A series of dry test transformers are combined into a series of test devices, which are convenient to use due to the scattered combination and can be suitable for various needs on site. Individual components are light in weight, easy to transport and move, and the use of higher voltage grade departments in the field can smoothly obtain higher test power supply.

2. Working principle

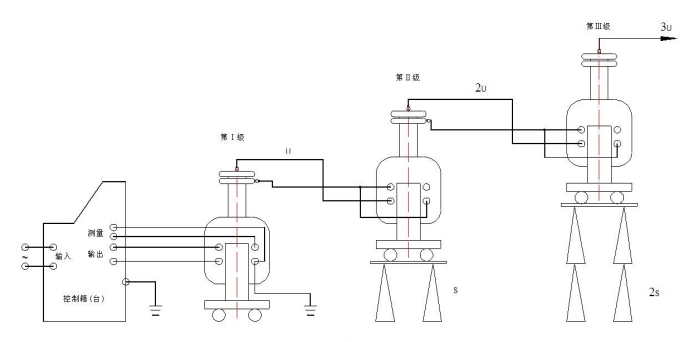

Series high voltage test device, except for the highest voltage of the first stage test transformer, are wound in series excitation winding in the high voltage winding, the winding and the next stage test transformer primary winding parameters the same.

The primary winding power supply of the grade I test transformer is provided by the control box (platform). The tail end of the class I high voltage winding is grounded to the shell, and the head end is connected to the high voltage tail end and the shell of the Class II test transformer. The excitation power supply of the low-voltage winding of stage II is supplied by the series tap of stage I. At this time, the high voltage of the stage II test transformer is the superposition of the output voltage of stage I and Stage II. Similarly, level III can be superimposed.

3. Assembly wiring

4. Cascade combination

4.1 When the two test transformers are connected in series, the ratio of the capacity of the test transformer in Set I and Set II is 2:1, the total capacity is the capacity of set I, the total voltage is the sum of the highest output voltages of two single sets, and the current is the ratio of capacity to total voltage. Example: 5kVA/50kV and 3kVA/50kV. The total capacity of two cascade is 5 kVA, the total output voltage is 100 kV, and the output current is 50mA.

4.2 When the three test transformers are connected in series, the capacity ratio of the three transformers is 3:2:1, the total capacity is also the capacity of the I transformer, and the total voltage is the sum of the output voltage of the three transformers.

Note: No matter two-stage series or three-stage series, the output current is strictly prohibited to exceed the rated current of the last stage.

Special notes

The high voltage tail of the test transformer and the end of the measuring coil are connected internally. When used, the class I high voltage tail together with the shell must be well grounded. The class II and III high voltage tail together with the shell must be fixed potential.

In the cascade high voltage test, special attention should be paid to check the correctness of the wiring of grade II and III, because the reverse connection will cause the output voltage to be zero, so the voltage divider can be used to directly monitor the high voltage output. Also check whether the electrical strength of the insulation support meets the voltage requirements.

Wuhan Xinshengneng Technology Co., Ltd. is a professional transformer tester manufacturer, producing series resonance, power frequency withstand voltage test device, DC high voltage generator and ultra low frequency high voltage generator of various models and specifications. Wuhan Xinshengneng Technology Co., Ltd. serves you: 0312-3188565. For more information, visit wuhan Xinshengneng Technology Co., Ltd. official website: www.whxsn.com